BREAKING NEWS

Source: Plastic Soup Foundation

In the last year, the Institute for Polymers, Composites and Biomaterials of the Italian National Research Council (IPCB-CNR) and the Netherlands-based Plastic Soup Foundation tested synthetic clothes from four global fashion brands. The results will be presented during the trade fair ISPO in Munich on Monday, February 4th from 4pm to 5pm, at the Press Center West.

THE FINDINGS

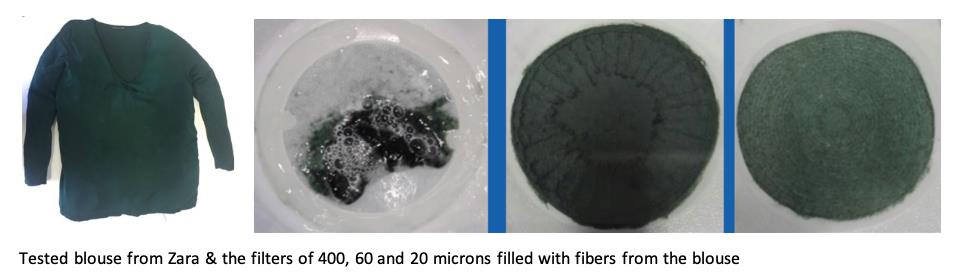

This blouse from Zara – made of 100% polyester on the front and a blend of cotton and modal on the back – lost so many fibres per wash that it started “disintegrating” after only few washes. It lost an average of 307,6 mg of fibres per kg of laundry.

Maria Westerbos, director and founder of the Plastic Soup Foundation, states: “This is what you call fast fashion. It disappears in front of your eyes.”

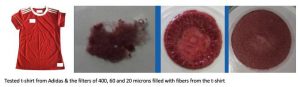

The tested t-shirts from both Adidas and Nike are made of 100% polyester and lost a very similar percentage of mg of fibres per wash: 124,05 mg/kg and 125 mg/kg, respectively.

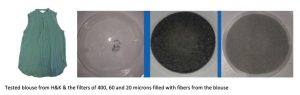

The H&M blouse that was tested contained 65% of recycled polyester. The loss of fibres from this blouse was still high but, surprisingly, it performed better than the other brands, losing an average of 48,6 mg per kg of wash.

The method used in determining the quantity of lost fibres was similar to the one Plymouth University used on their research in 2016. Both institutes weighed the filters before and after filtration in order to evaluate the number of microfibers released in grams. The main difference between the two is that IPCB-CNR used three filters and washed whole garments, while Plymouth University used one filter and washed small pieces of fabrics. Nonetheless, the outcome of both research projects is comparable.

Further specifics: IPCB-CNR washed the garments two times using the same methodology for all of the tests:

- a Bosch washing machine

- washing load of 2-2.5 kg

- the program for synthetic clothes at 40ºC & 1200 rpm

- using liquid detergent

- the wastewater was filtered through three filters with a mesh size of 400, 60 and 20 microns; the latter filter contained openings two times smaller than a human hair.

Maria Westerbos: “IPCB-CNR wrote a scientific paper on the performed tests which is being peer-reviewed and will soon be published. Although the outcome is shocking and three out of the four fashion brands perform ‘badly’, we cannot completely compare them. It all depends on what fabric has been used and how the yarn is made: what (combination) of materials, but also if the fibres are long or short, or if the yarn is woven or knitted. We need a benchmark to be able to compare yarn, but no fashion brand in the world is willing to pay for that. It makes me so sad.”

Solutions along the value chain

Another important issue is that regular washing machines are not capable of filtering out microfibers that are released during the washing process. For that reason, the Plastic Soup Foundation supports an innovative (add-on but also internal) filter created by the Slovenian start-up company Planet Care. Two of the four garments that were tested by IPCB-CNR, used this Planet Care filter as well, and the results were outstanding: up to 80% of the fibres got caught before entering the wastewater. Westerbos: “The t-shirts from Nike and Adidas were washed one more time in order to test the filter, with a successful outcome. Although this solution is end-of-pipe, it is at least a working solution. I advise washing machine manufacturers to implement this a.s.a.p. in their washing machines.”

Besides the filter, there is another – beginning of pipe – solution that seems extremely promising. As part of the Mermaids Life+ research (2014-2018), IPCB-CNR developed a pectin coating that can be added to the yarn and could potentially prevent more than 80% of microfiber release. At the moment, more research is being funded by yarn manufacturer Sympatex Technologies.

Sympatex also asked IPCB-CNR to test the loss of fibres from functional textiles, used in outdoor clothing. The initial results of these tests will also be presented at a press conference during the trade fair ISPO 2019 in Munich on February 4th from 4pm to 5pm, at the Press Center West.

Sympatex, the Plastic Soup Foundation, IPCB-CNR, Plastic Leak Project, Planet Care and Ruby Moon are collaborating to explore and find solutions to microfiber release from synthetic clothing.

Background information

Synthetic clothes are a menace to animals and humans

The Plastic Soup Foundation is very unhappy with the outcome of the washing tests and urges brands to take responsibility and make the materials more sustainable, not only during the production phase but also during wear. Acrylic, polyester, nylon and other man-made materials do not biodegrade in the environment, they fragmentize into ever smaller pieces. The Plastic Soup Foundation holds clothing manufacturers responsible for the whole life-cycle. Last year, these results were shared with the tested brands to give them the opportunity to react and make necessary changes. Until now only Adidas is active in a search for possible solutions. No response has been given and no action has been taken by the other three brands since.

Synthetic clothes are one the biggest environmental threats of our time; they are responsible for more than one-third of all microplastics – plastic particles smaller than 5mm – polluting our oceans. Synthetic materials represent about 60% of the clothing material worldwide, and out of this percentage, the most used one is polyester. The omnipresence of clothing made from synthetic materials is irrefutable, and microplastic pollution from clothes which passes undetected through wastewater treatment plants, are also making their way into humans. Microplastics have been found in fish, plankton, chicken, sea salt, beer, honey and in tap as well as bottled water. We are also breathing in these plastic particles due to fibre loss by our carpets, curtains, and other textiles.

The Sustainable Apparel Coalition could implement the loss of fibres in the world wide’s most sustainable tool: The Higg Materials Sustainability Index, but for that it needs a benchmark as a tool to compare test results.

IPCB-CNR and the Plastic Soup Foundation collaborated before in the Mermaids Life+ research, an EU-funded project with the goal of monitoring and mitigating the number of microfibers released during laundry processes.

Press enquiries to:

Maria Westerbos, Founder & Director | Plastic Soup Foundation

E-mail: maria@plasticsoupfoundation.org

Phone number: (+31) 06-510 906 91

Jeroen Dagevos, Head to Programs | Plastic Soup Foundation

E-mail: jeroen@plasticsoupfoundation.org

Phone number: (+31) 06-468 378 86

Maurizio Avella, Research Director | IPCB-CNR

E-mail: maurizio.avella@ipcb.cnr.it

Phone number: (+39) 081 8675058